Modular Briefcase

Organization and Interior Utility

The Design Concept

The System of Space briefcase serves as a study in translating complex apparel construction into a functional 3D volume. Originating as a school project requiring a standard two-compartment bag, I chose to expand the brief by developing an intricate interior organizational system.

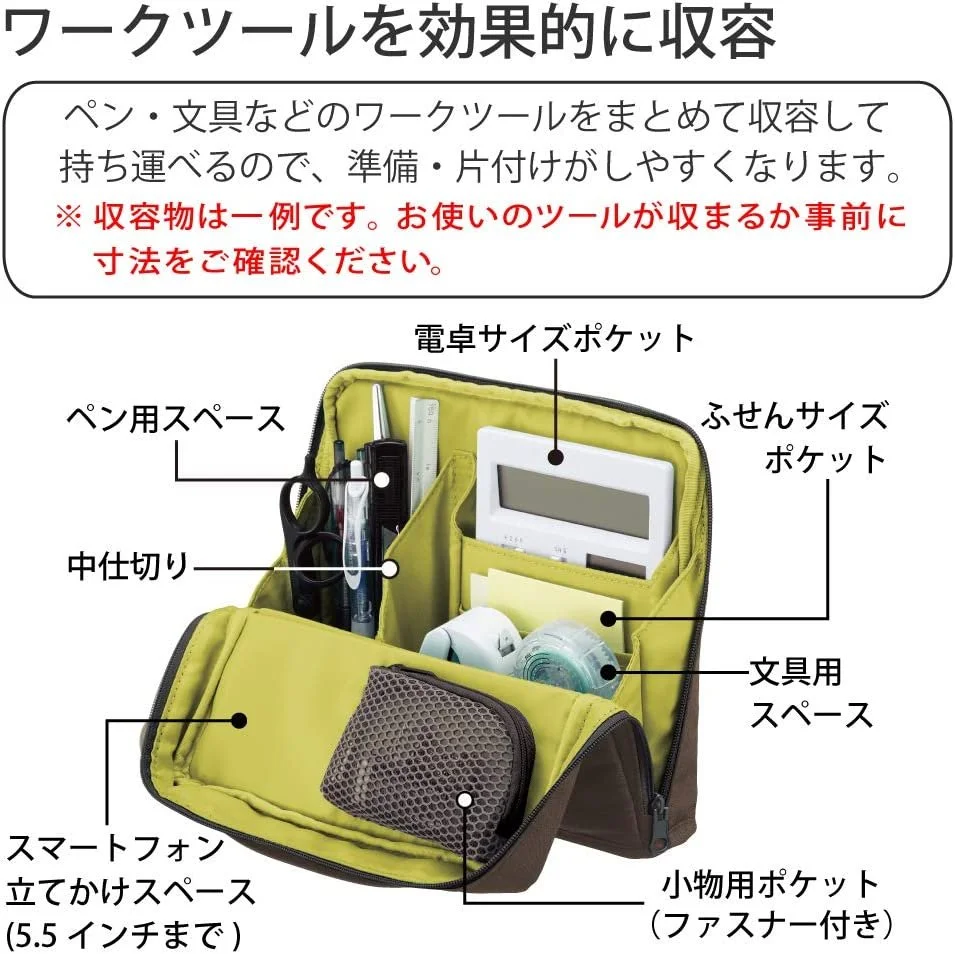

Inspired by the functional ergonomics of Japanese stationery cases, specifically the tiered storage logic of brands like Lihit Lab, the design hides a high-density utility grid behind a minimal waterproof exterior.

Material Logic and Sourcing

Sourced from industrial suppliers, including Wawak and Ohio Travel Bag, the material selection focuses on durability and structural integrity:

The Shell:

10 oz Olive Green Waxed Canvas for weather resistance

The Lining:

Charcoal 2-Ply Nylon Taslan for a high-strength, moisture-resistant interior

Support:

1/8 inch Closed-cell Polyolefin foam and non-fusible interfacing

Hardware:

Industrial-grade #5 nylon coil zippers, Prym snaps, and seatbelt-grade nylon webbing for the carry system

Interior Architecture: The Three-Wall System

The interior utilizes a three-wall layout (A, B, C) to organize the two primary compartments into a series of specialized zones:

Modular Flexibility:

The side walls are engineered with box-stitched Velcro strips, allowing them to be partially detached. This modularity enables the user to reconfigure the internal volume between a structured grid and a larger open void.

Storage Density:

The system features over 15 dedicated storage points, including a foam-padded laptop sleeve, tiered slip pockets, a mesh elastic pocket, and grosgrain hanging tabs for hardware and peripherals.

The Process

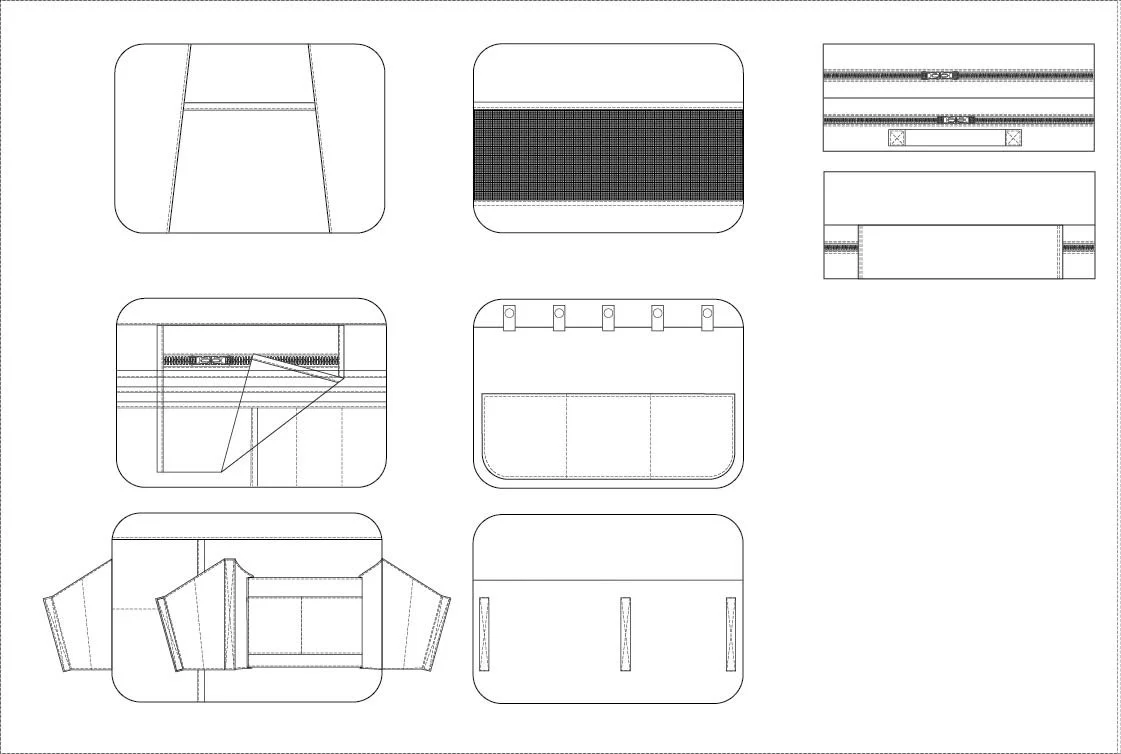

The project required a shift from flat-patterning to 3D box construction. I mapped the initial storage schematics in Adobe Illustrator before drafting the patterns in Optitex. I executed the full production cycle independently, following a 40-step industrial Sequence of Construction (SOC). This workflow was critical for calculating turn-of-cloth allowances and ensuring the 3D corners maintained the precision of the initial digital draft.

Technical Specs

Patterns: 45 digitally drafted pieces (Optitex)

Dimensions: 15" W x 10.5" H x 6" D

Assembly: 40-Step Sequence of Construction

Finishing: 3/8" Twill tape-bound internal seams