The development of this layering system centered on a specific challenge in pattern optimization: creating high-performance hiking gear that eliminates excess bulk without sacrificing protection. The focus was on smarter patternmaking, refining the geometry of each garment so that every shape serves a functional purpose and aids the wearer’s range of motion.

By sourcing premium technical textiles, including Swiss-engineered Schoeller® stretch-wovens alongside performance materials sourced in the USA and Canada, the 6-piece system achieves a streamlined fit through extensive pattern engineering rather than simply reducing volume. Strategic articulation and precise seam placement remove the fabric bunching typically found in outdoor apparel, resulting in a durable, backcountry-ready capsule that supports the hiker through high-output movement.

cuan:o

the 6-piece kinetic system:

I. Protection

Waterproof Hardshell

3-layer membrane construction, fully seam-taped for total weather protection.

II. Thermal

Quarter-Zip Pullover

Polartec® 200 Curly Fleece for static warmth and comfortable feel.

Zip-Through Mid-Layer

Polartec® Power Stretch for active moisture-wicking and heat regulation.

III. chassis

360° Trek Pant

Built-in articulation for maximum mobility and heat-applied double-knee reinforcements for targeted abrasion resistance.

Summit Cargo Pant

High-recovery mobility for high-output hiking.

Kinetic Utility Short

High-durability utility for rugged trails with a low-profile pocket system.

a/w 2023

Title: 01. PERFORMANCE RAIN SHELL

Category: Outer Layer / Waterproof-Breathable | Focus: Pattern Optimization & Tactical Construction

The Concept

Designed as the primary protective layer for the CUAN:O system. The goal was to eliminate the bulk of traditional "lifestyle" parkas in favor of an unlined, high-mobility shell that facilitates quick adaptability in unpredictable environments.

Textile Performance & Sourcing

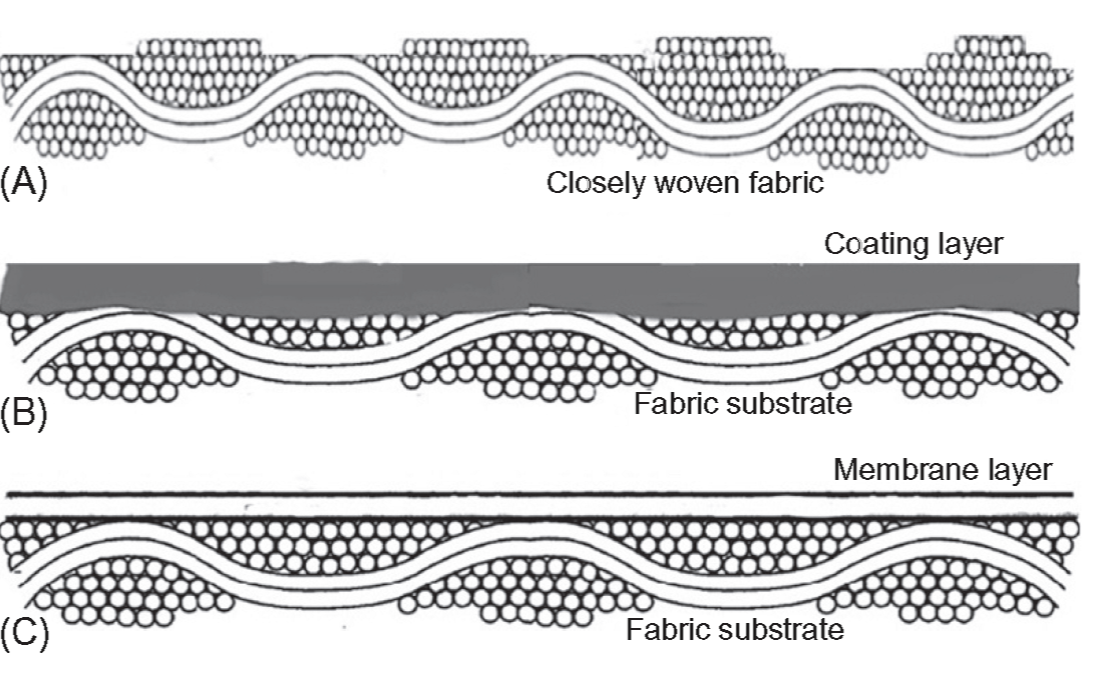

Fabric: 3-Layer Ultrex (PU-based membrane) with Tricot backing:

Total Weight: 4oz/sq.yd +/-5%

Fiber & Weave: 100% Nylon, Plain Weave

Finish: DWR, Micro Porous Waterproof Breathable

The Logic: Selected 3-layer construction over 2.5L for superior structural integrity and seam-tape adhesion.

Sustainability & Repair: 3-layer system enables easier tape removal and reapplication via heat press, significantly extending the product’s lifecycle compared to 2-layer alternatives.

Alternative Sourcing: Navigated North American supply chain constraints by sourcing high-performance Ultrex as a viable, flexible alternative to ePTFE membranes for small-batch technical production.

Master pattern (Front and Back) with drafted design lines in Optitex working space

Zach Mike (model) showing the shell’s fully seam taped interior

Waterproof Hard Shell patterns and pieces table. 27 pattern pieces and 47 total cut pieces

software & Execution

Patternmaking: Manual & Optitex.

Documentation: Comprehensive Tech Pack developed in Excel.

Prototyping: 100% self-constructed, including manual seam sealing and hardware integration.

Complete tech pack created in Excel

Technical Features

3D Ergonomic Hood: Modified from an Arc’teryx anatomical block; refined in Optitex for a snug, non-helmet-compatible fit with a double-laminated visor.

Hardware: YKK AquaGuard® Coil Zippers; dual-cinch cord adjusters.

Laminated Details: Adhesive-bonded hood and cuff facings to reduce needle-hole exposure and create a "clean" modern finish.

3 - panel hood design with hood facing and visor interfacing in Optitex working space

a prototype made out of stiff coated cotton

Final hood- 3/4 view

Final hood- Profile view

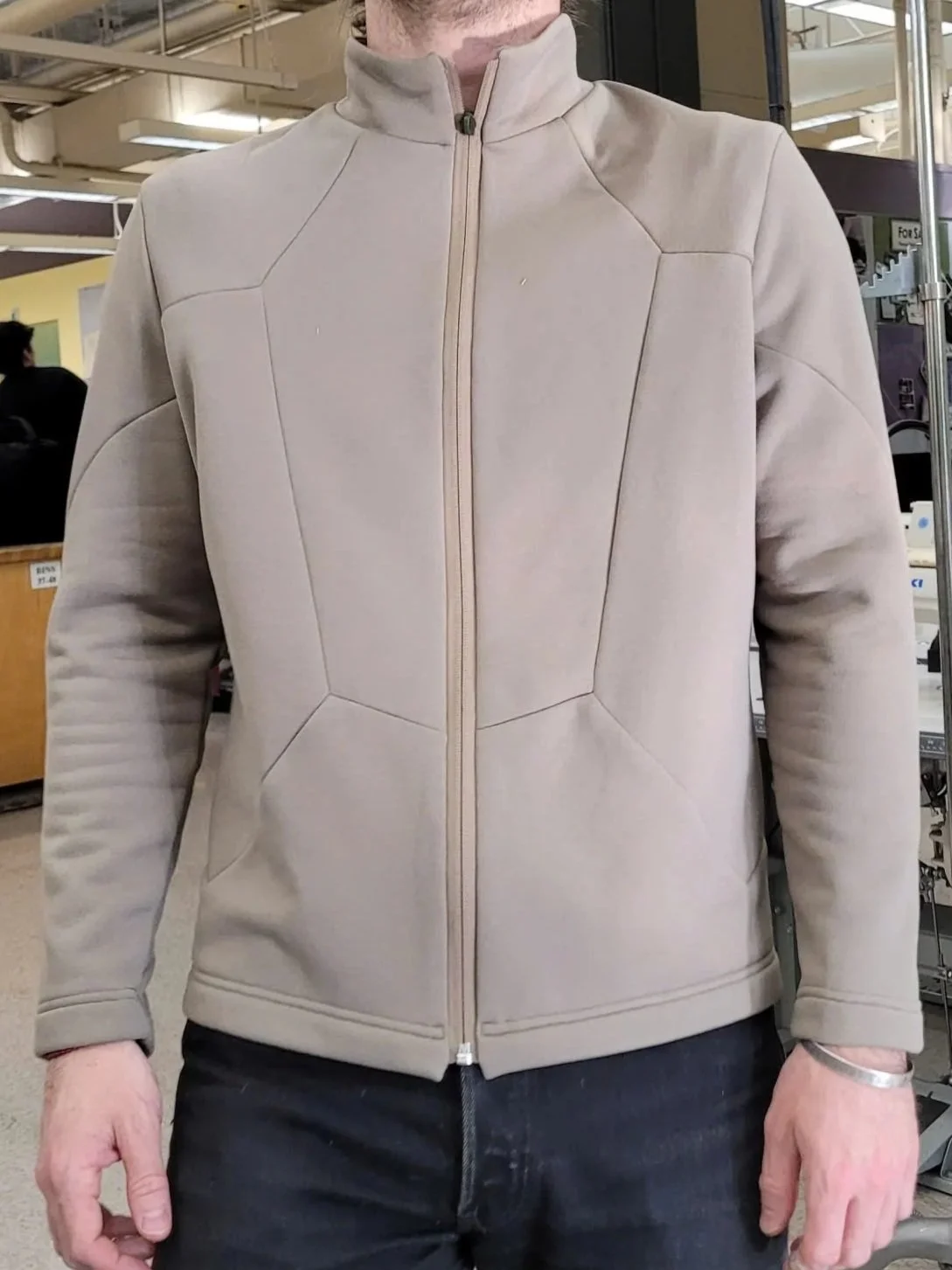

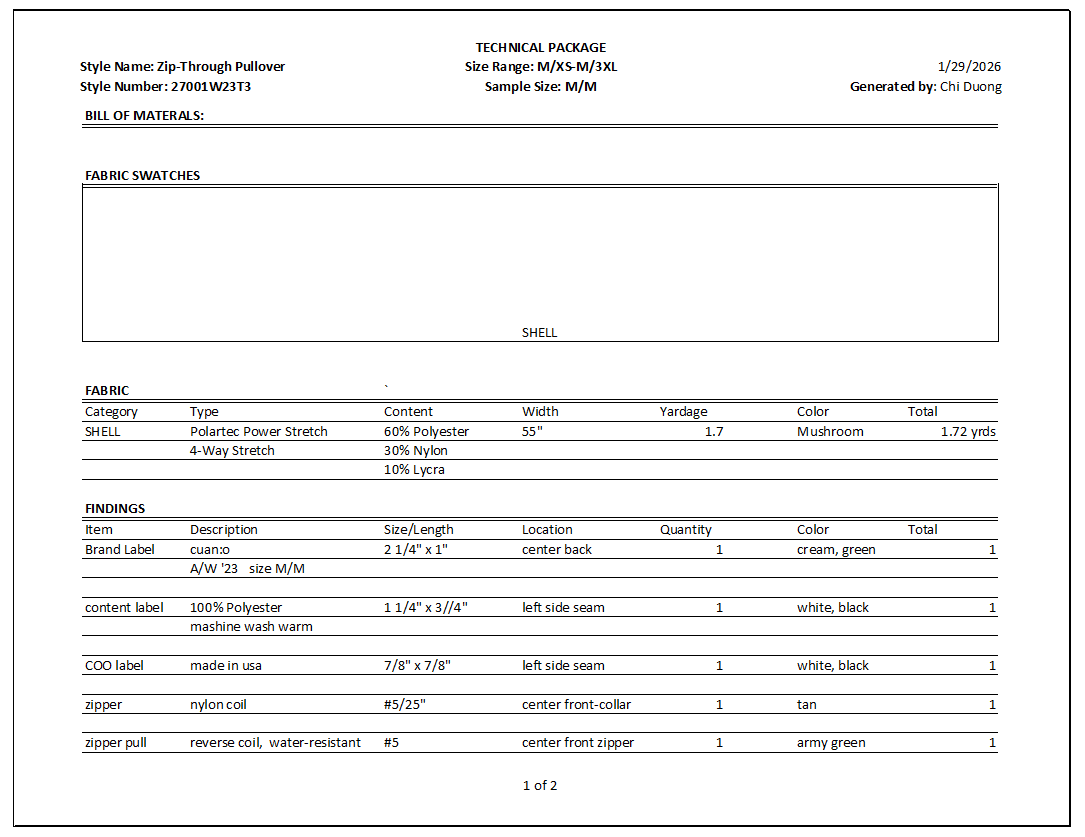

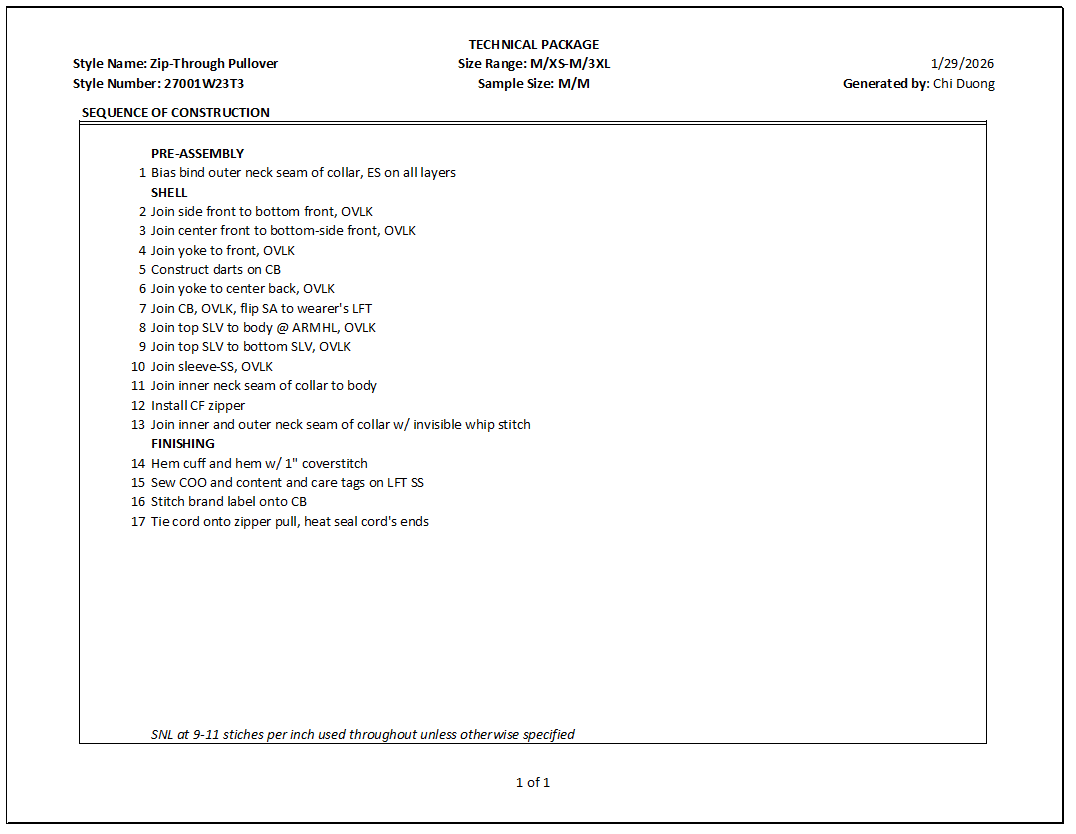

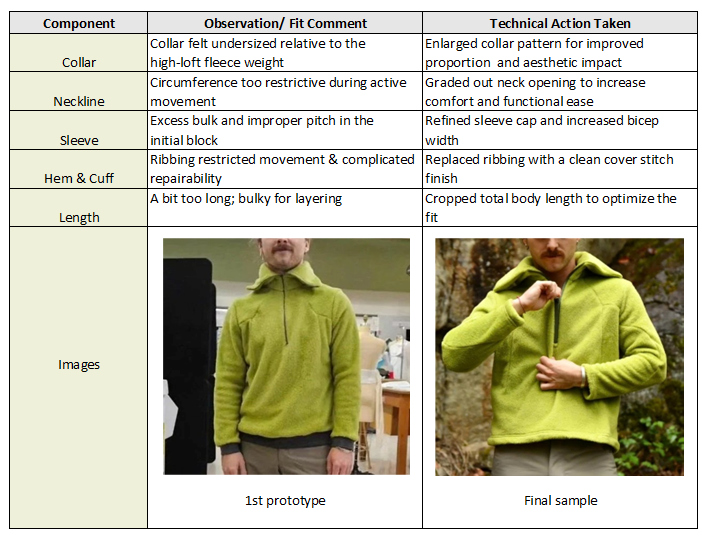

Title: 02. zip-through midlayer

Category: Thermal Mid-Layer | Weight: 240 GSM | Fit: Semi-fit

The Concept

A packable thermal layer designed for high-intensity adaptability.

Cohesive Design Language: Features calculated design lines on the torso that establish a visual rhythm with the rest of the capsule. These lines serve as a "Mountain and Valley" signature, ensuring aesthetic consistency across the layering system.

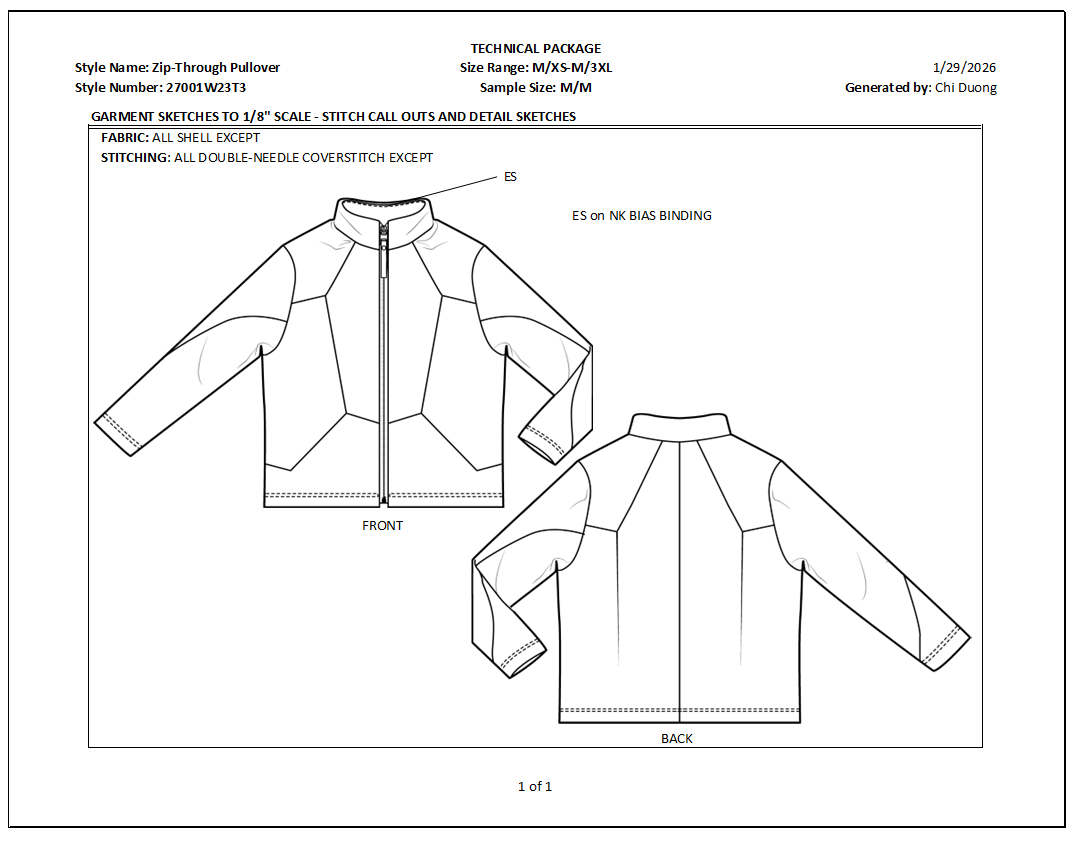

FRONT

BACK

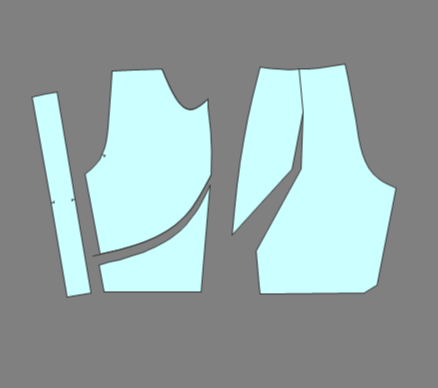

2D Optitex pattern blocks vs. finished prototype

technical Specifications

Fabric: Polartec® Power Stretch™ (Nylon/Polyester/Spandex).

Performance: 4-way stretch with dual-surface knit (Low-friction face / Brushed interior).

Hardware: Size 5 YKK Reverse Coil Zipper and YKK slider for a low-profile, debris-resistant finish.

Construction: 4-thread serge + Coverstitch for flat, chafe-free interior seams.

Clean Finishing: A fold-over neck panel and a bound neck seam to provide a refined, low-profile finish at the neckline.

Close-up: Different seam finishes and garment tags (Main label, COO & Care Instructions)

software & Execution

Patternmaking: Optitex.

Documentation: Comprehensive Tech Pack developed in Excel.

Prototyping: self-constructed.

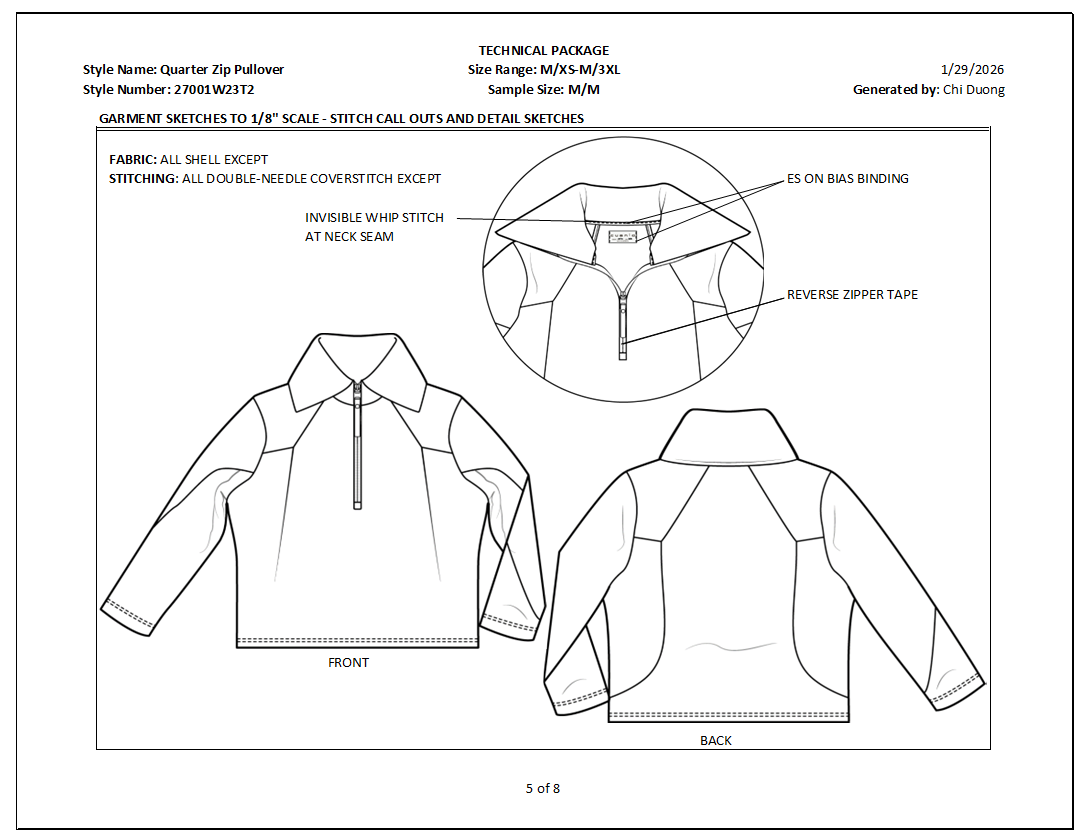

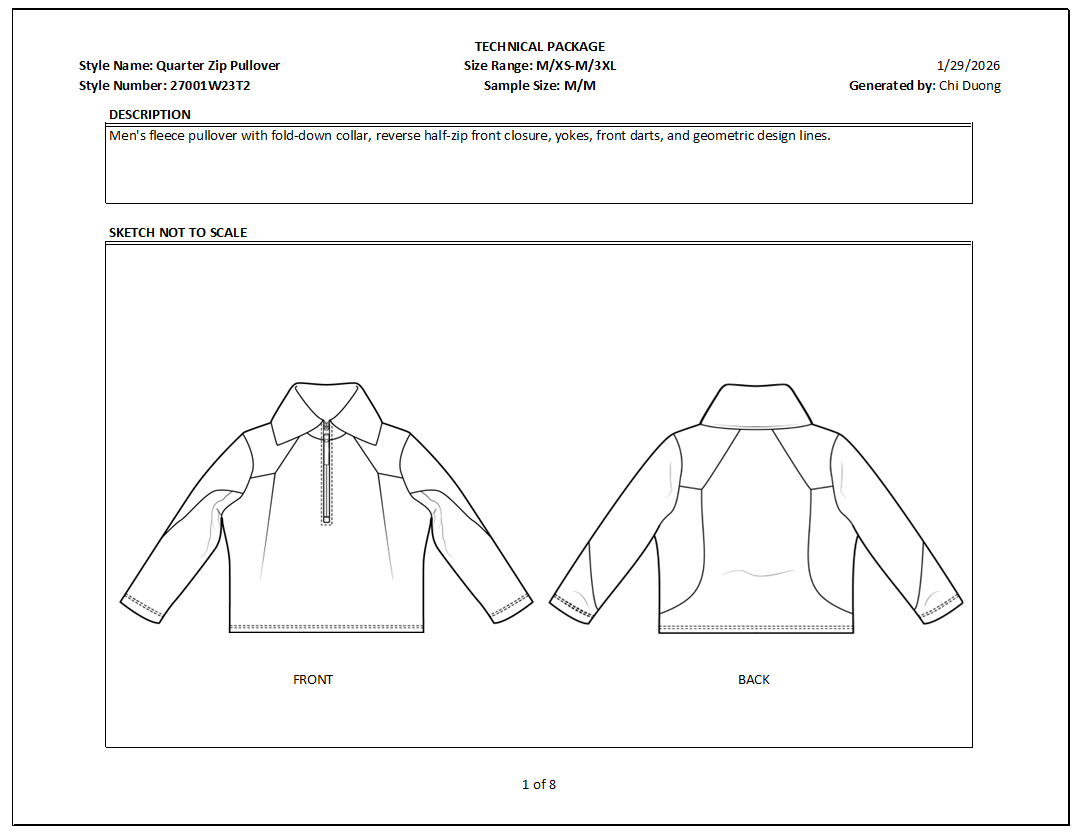

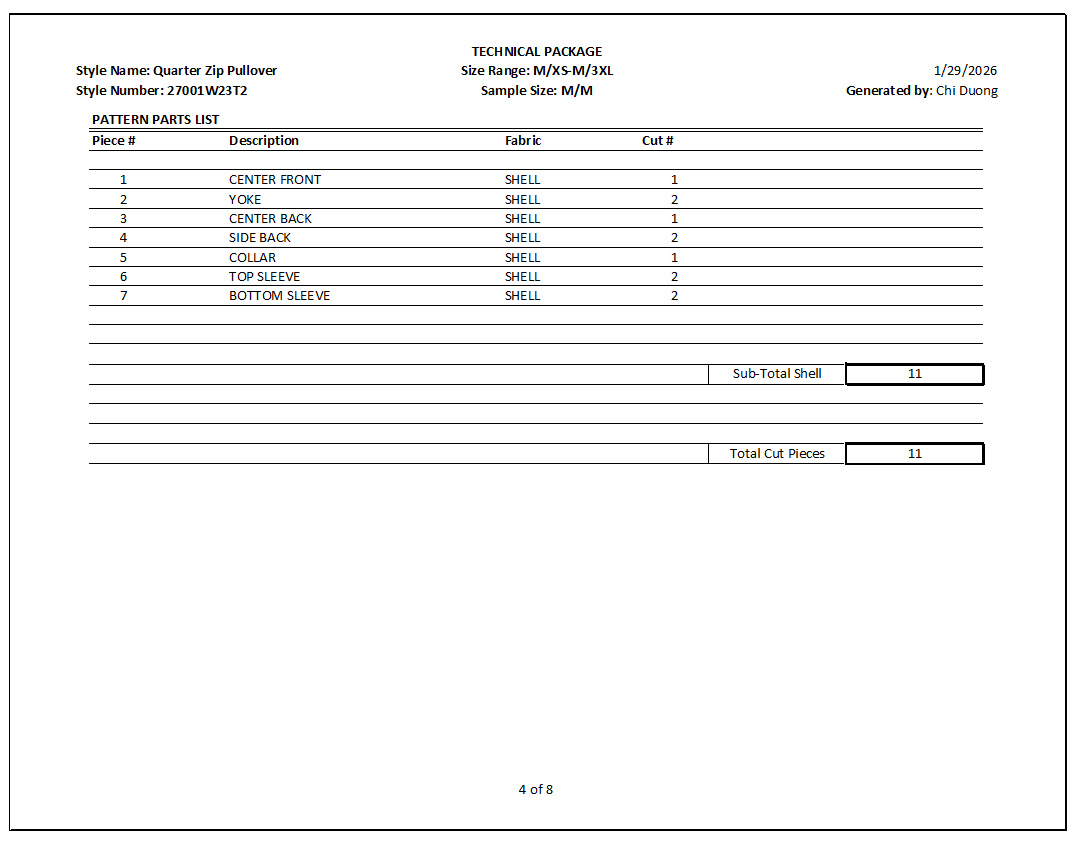

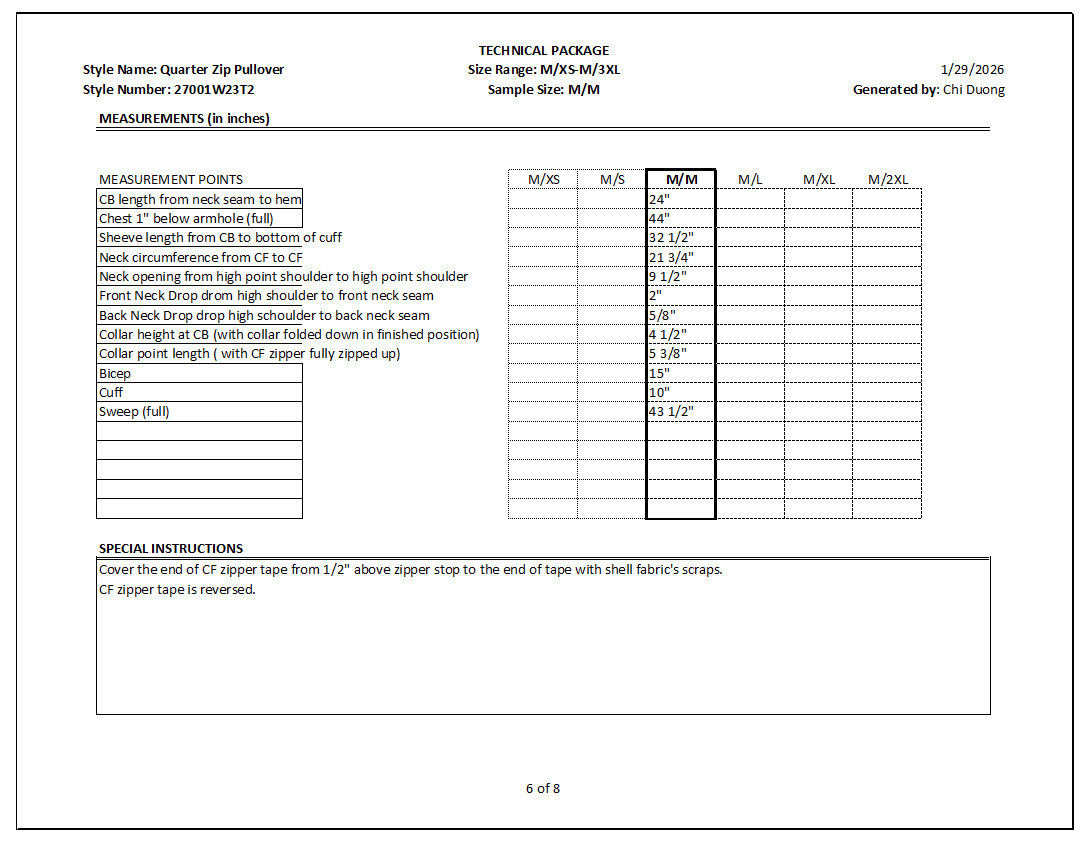

Title: 03. quarter zip pullover

Category: Thermal Mid-Layer | Weight: 200 GSM | Fit: Relaxed-Active

The Concept

A high-loft alternative to the zip-through midlayer, offering increased thermal retention with a more relaxed, versatile silhouette. Designed for urban-to-alpine utility, it maintains the capsule's core visual identity while prioritizing comfort and sustainable material choice.

Technical Specifications

Fabric: Polartec® 200 Series Fleece (High-loft / 100% Post-Consumer Recycled Polyester).

Sustainability: Utilizes PCR (Post-Consumer Recycled) plastic bottle fibers, reflecting a commitment to eco-conscious technical sourcing.

Design Integration: Features an oversized rectangular fold-over collar and signature geometric line-work. Inverted front-panel darting provides subtle contouring while maintaining alignment with the capsule's "Mountain and Valley" design language.

Hardware: Size 5 YKK Reverse Coil Zipper and YKK slider for a low-profile, debris-resistant finish.

Clean Finishing: Internal bound neck seams ensure comfort and structural stability at high-friction points.

Tristan Sokol (model) in motion, wearing the Quarter Zip Pullover

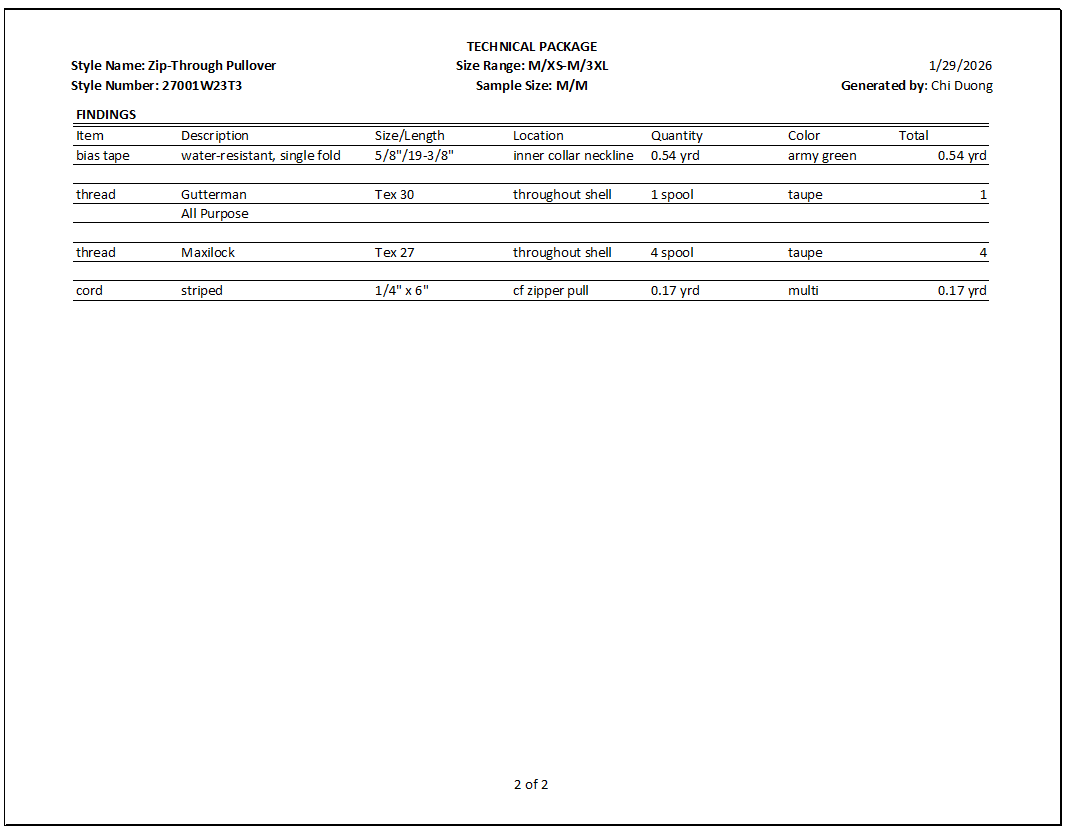

Fit Revision Log

A systematic audit was conducted on Proto 1 to address functional constraints and aesthetic proportions. The transition from a traditional ribbed finish to a technical coverstitch was prioritized to enhance repairability and movement.

software & Execution

Patternmaking: Optitex.

Documentation: Comprehensive Tech Pack developed in Excel.

Prototyping: self-constructed.

FINDING THE RHYTHM: A STUDY IN COHESION

Designing these three tops was a lesson in visual consistency. I didn't want them to just "work" together functionally; I wanted them to speak the same language. By placing them side-by-side, the "Mountain and Valley" rhythm becomes clear, it’s a visual hand-off that carries the energy of the outer shell down into the core mid-layers.

The core challenge was balancing sharp geometry with organic curves across all three tops, ensuring each variation felt distinct yet interconnected; solving that structural puzzle is ultimately what transforms the capsule into a single, cohesive system.

Even when you strip back the layers, the DNA remains. It’s that intentional alignment that turns three individual garments into a cohesive family.

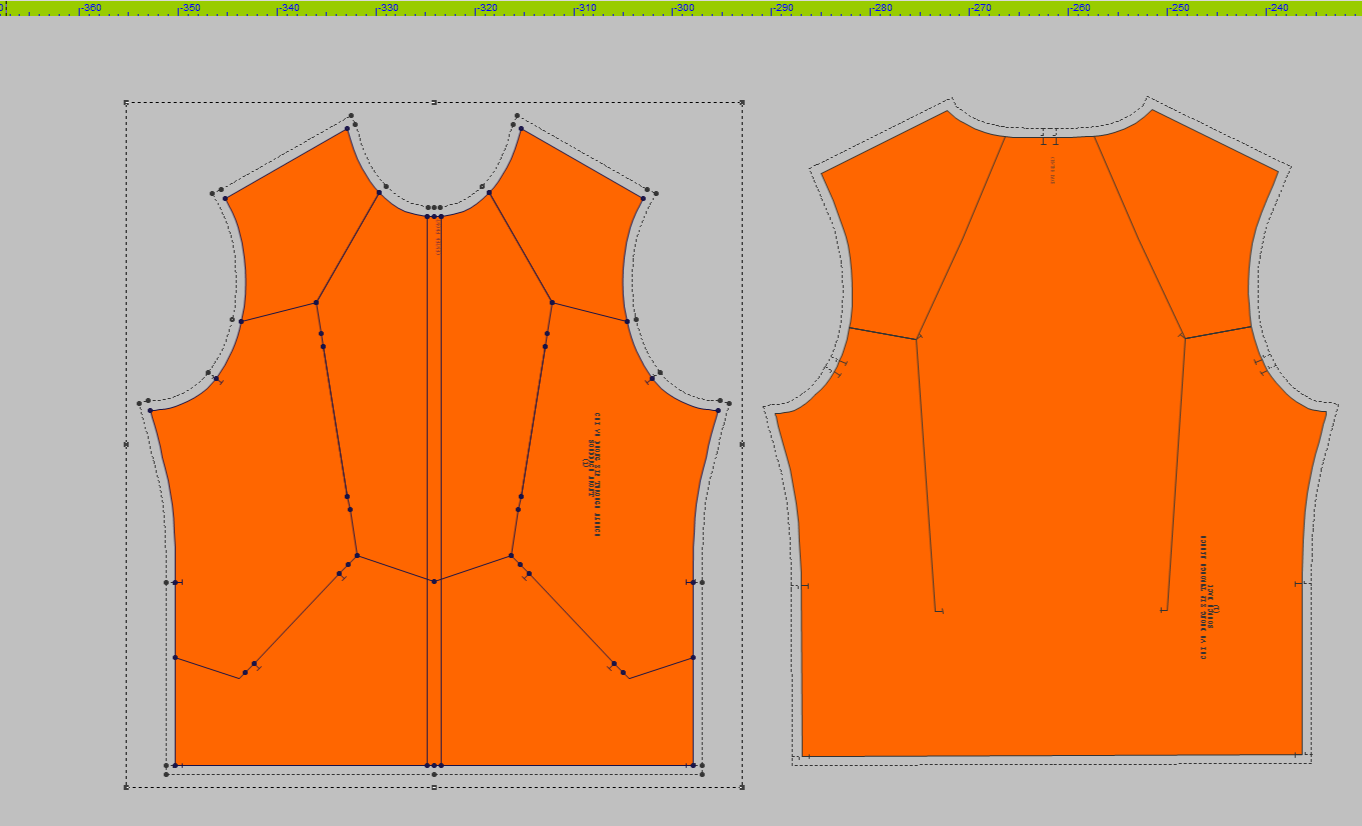

Upper-Body DNA: A side-by-side pattern blocks (Front & Back Torso) of the three core tops,

showcasing the intentional alignment of seam architecture as it transitions from the hard shell into the mid-layers.

Zip-Through Mid Layer (left), Hard Shell (middle) and Quarter Zip Pullover (right)

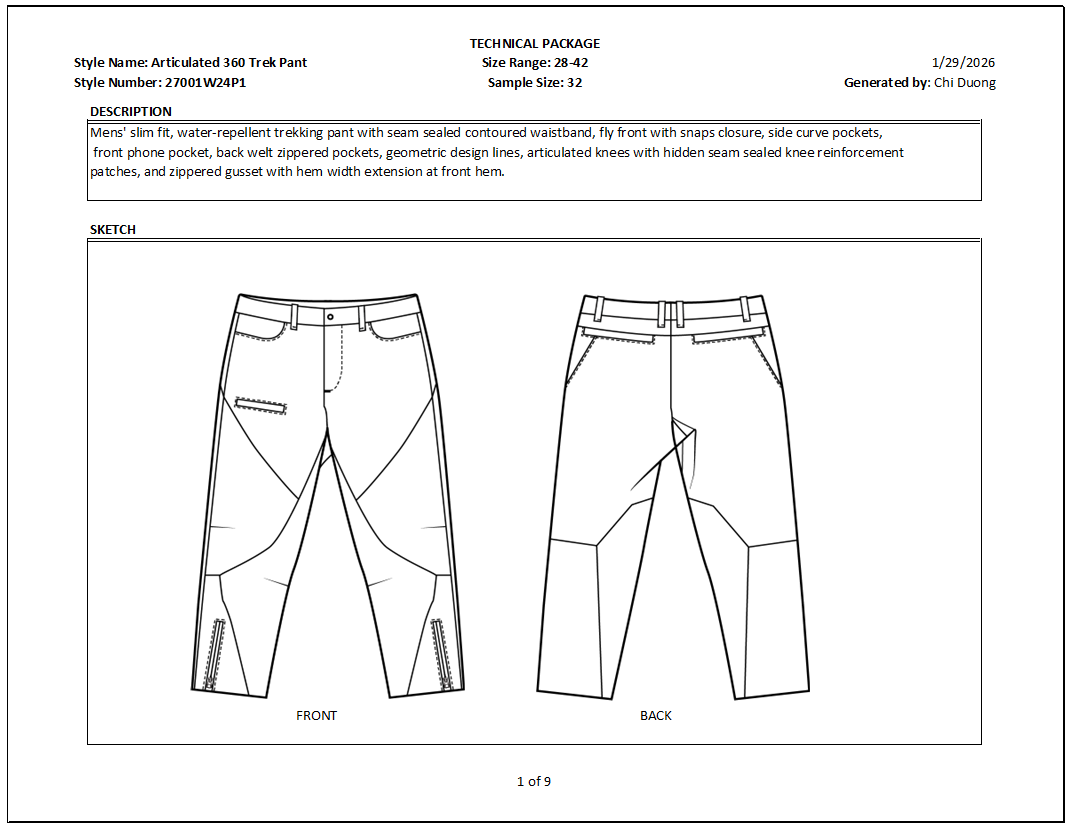

Title: 04. 360° TREK PANT

Category: Technical Shell | Fit: Tapered Articulated | Complexity: Very High

The Concept

The CUAN:O articulated 360°Trek Pant focuses on redefining the "second skin" experience in technical apparel. Moving beyond a standard slim-fit block, the design utilizes a 360° draft drafted to mirror the mechanical pivots of the human leg. By integrating 2D drafting with Virtual Fit Testing, the pattern-making process was optimized to eliminate material resistance during movement. The result is a high-mobility pant that provides structural protection while maintaining the fluid range of motion required for technical alpine terrain.

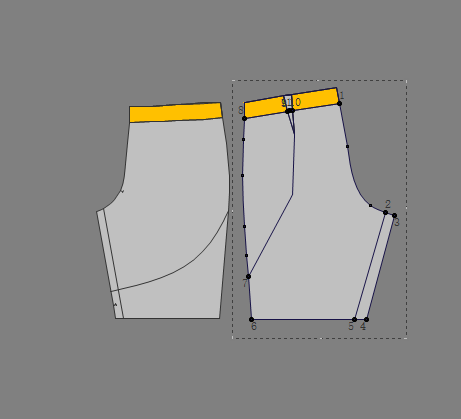

The use of Browzwear VStitcher was critical in achieving the precision fit required for this high-complexity pattern. By utilizing a digital avatar based on real-life fit model measurements, I was able to identify and resolve anatomical fit issues instantly without the need for multiple physical prototypes.

Because technical stretch-wovens are costly, the fabric simulation in VStitcher allowed for a level of accuracy that traditional muslin prototyping cannot provide. This digital-first approach significantly accelerated the refining process, moving from the initial block (left) to the final, snugged-down, high-performance fit (right) with maximum efficiency and minimal material waste.

Technical Specifications

Fabric: Adventure® Midweight Stretch Woven (92% Nylon, 8% Spandex) featuring an abrasion-resistant face, moisture-wicking back, and 4-way stretch with a DWR finish.

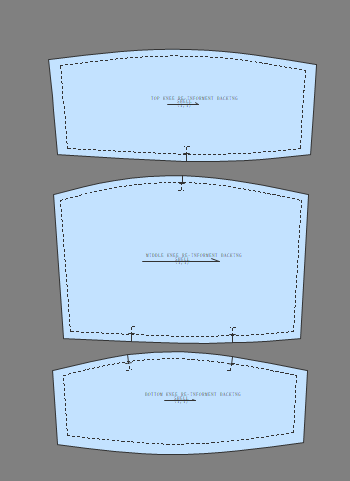

360° Articulation: Multi-panel construction at the front/back of the knee and inner thigh.

Stealth Reinforcement: Double-knee panels with hidden articulated padding, bonded to the interior for a low-profile finish.

Ergonomic Storage: Right-thigh welt pocket dimensioned via a 2023 user survey to ensure a bounce-free fit for modern smartphones.

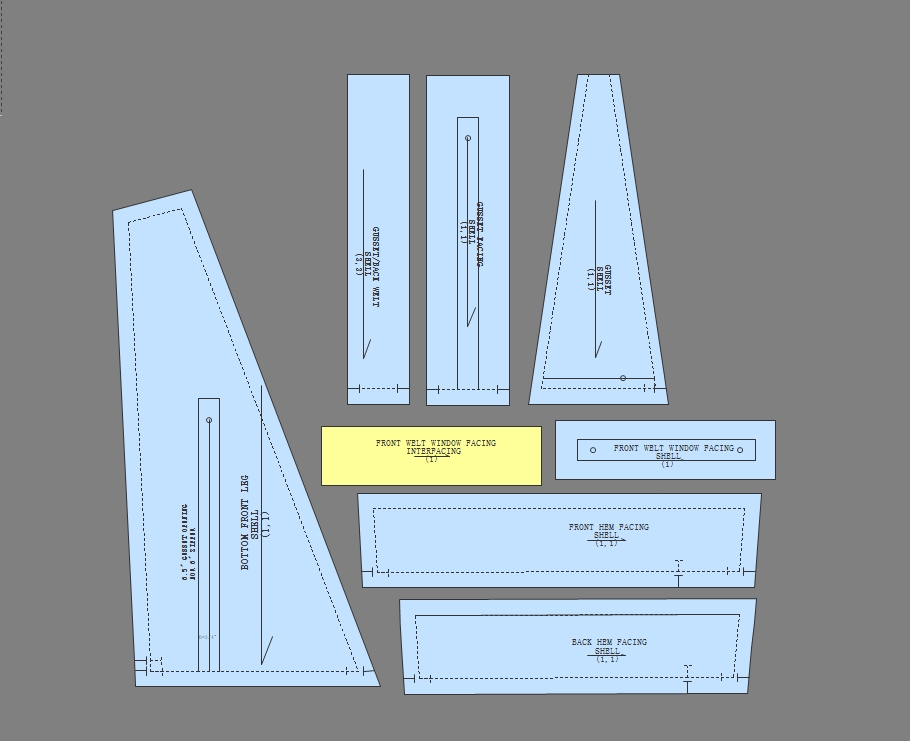

Adjustable Hem: Zippered gussets with welted tape coverage for compatibility across various outdoor footwear.

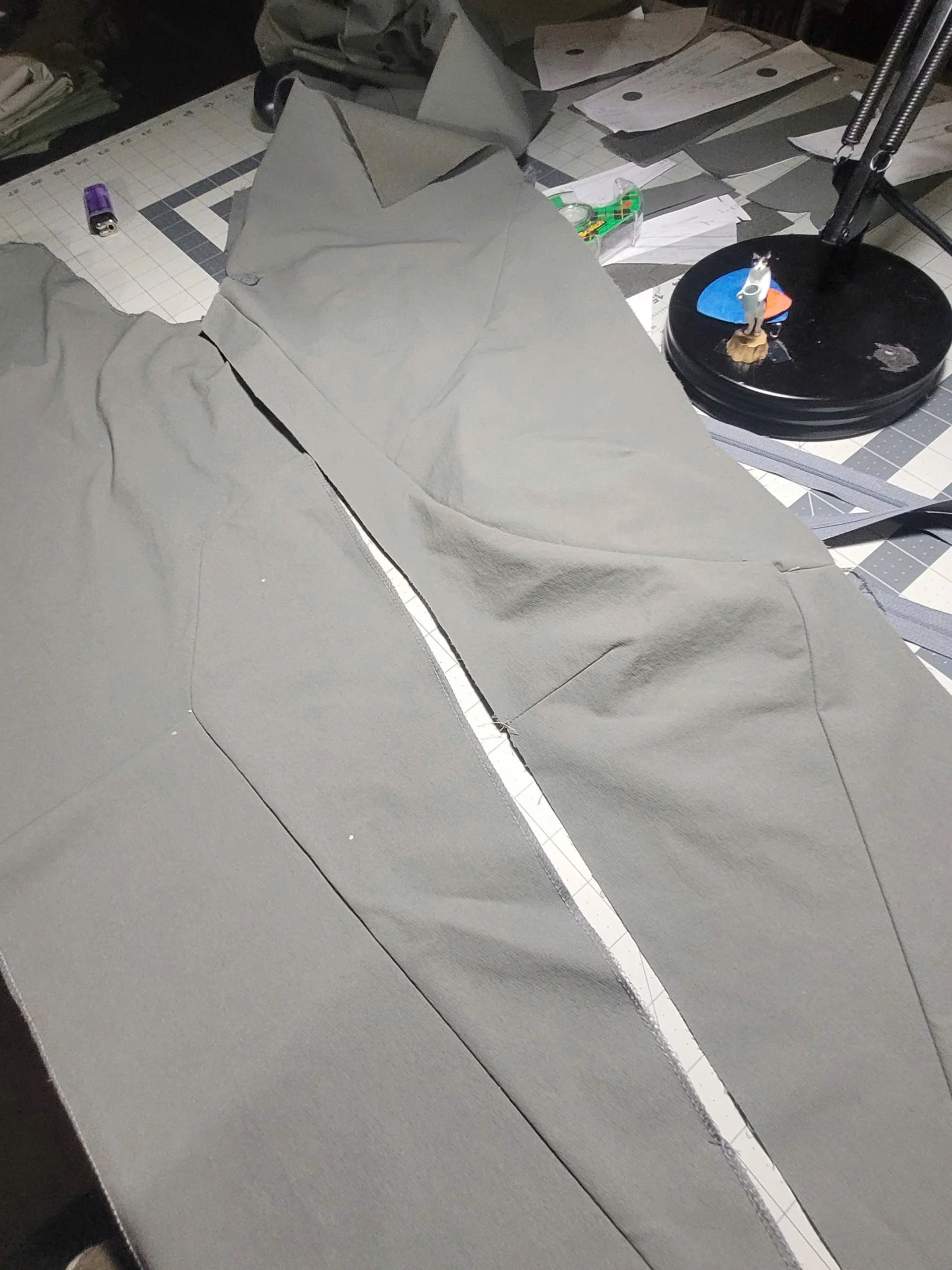

(up) Construction: Edge-stitching the gusset window onto the double-welt zipper tape (Step 7 of 28 - SOC)

Interior Architecture: View of mesh pocketing, serged seam finishing, and the integrated 3-panel contoured knee reinforcement.

Construction: Assembly of the contoured waistband and belt loops nearing final completion.

(up) 3D Volume: Front and back leg panels displaying inherent structural contouring even when laid flat.

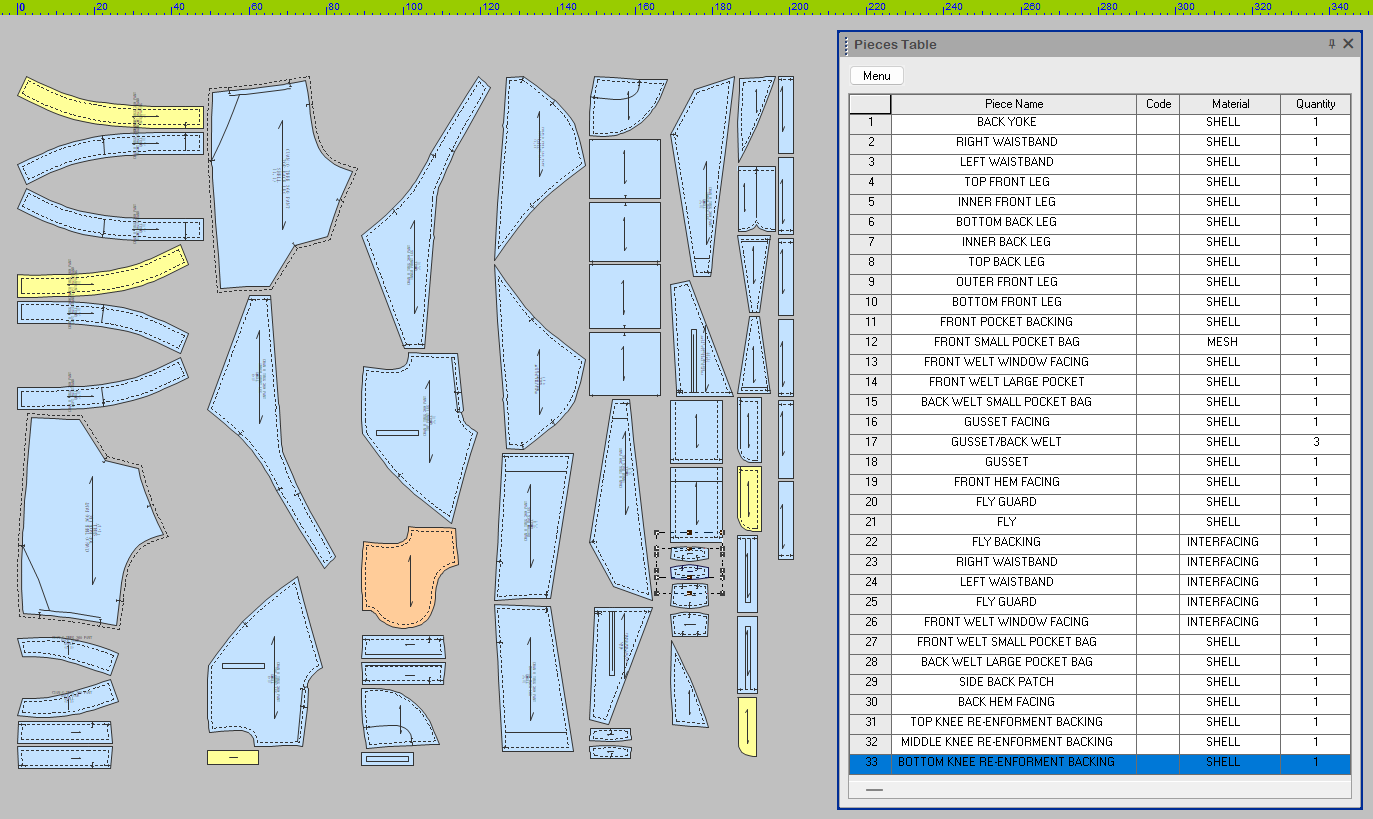

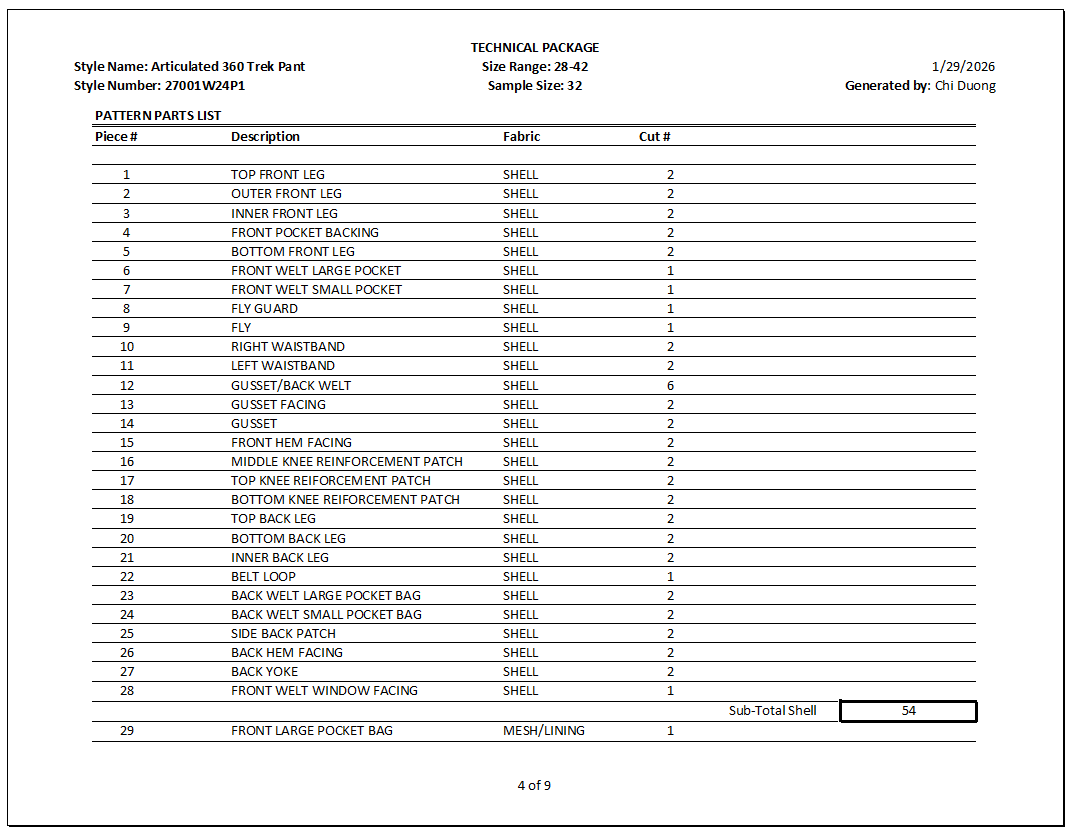

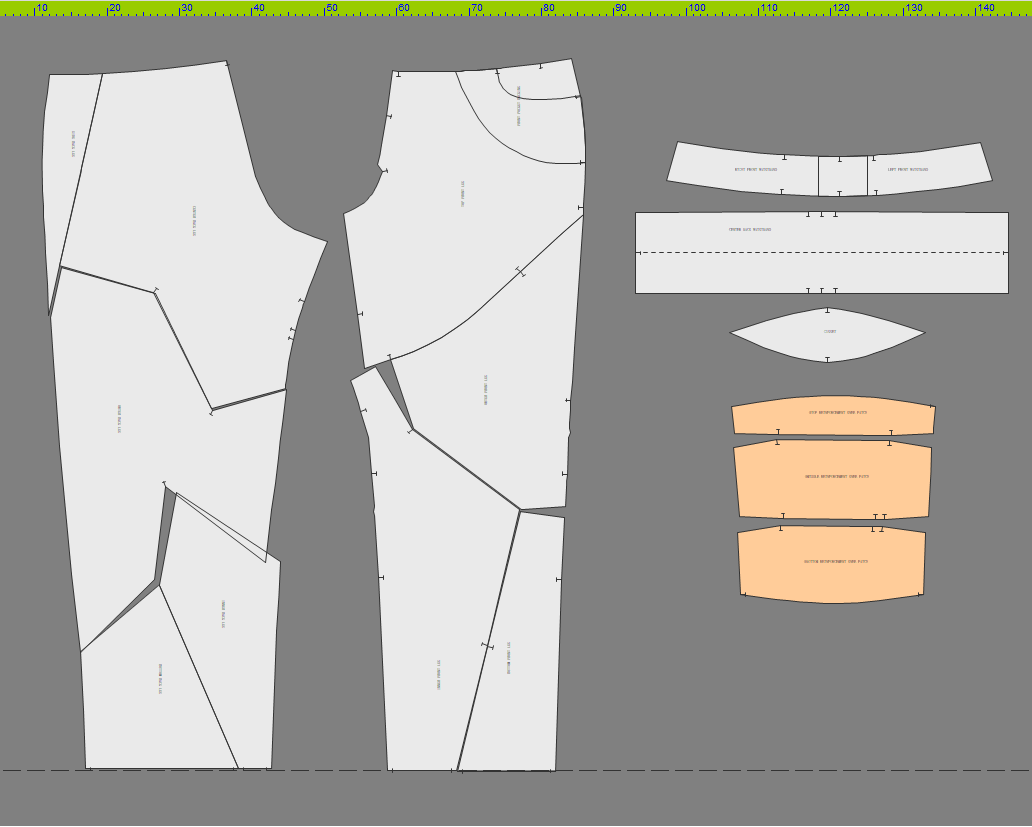

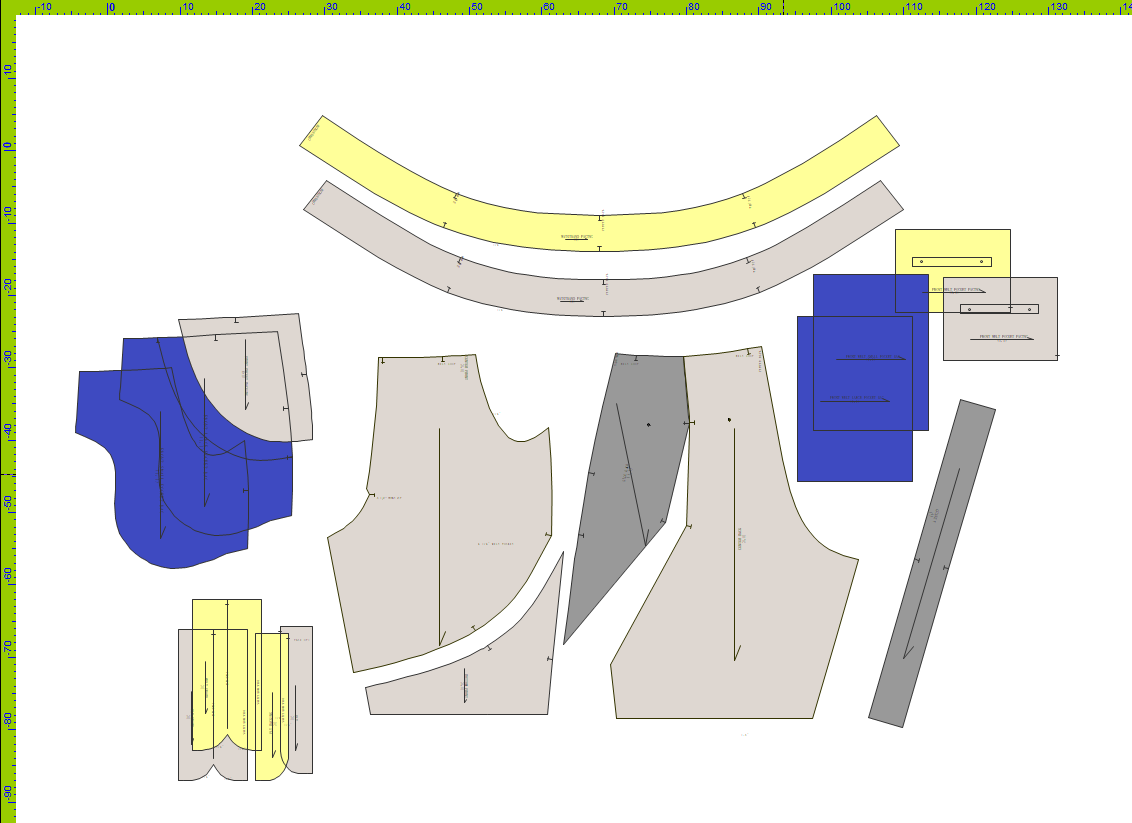

Optitex workspace displaying the 33-pattern piece assembly and pattern pieces table

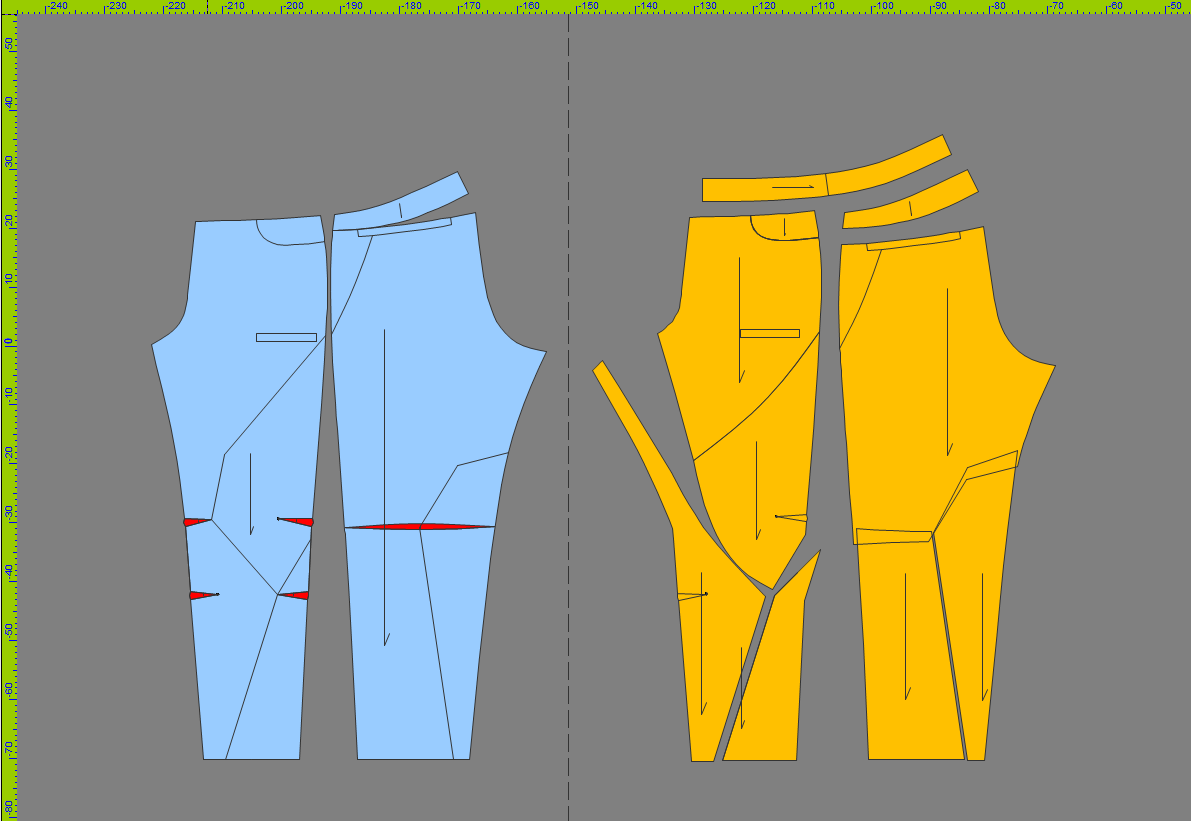

PATTERN logic: ANATOMICAL shaping

[Left: Mapping Mobility | Right: Final Pattern Geometry]

The articulation was developed by translating human anatomy into 2D geometry. I began by identifying high-motion zones to place strategic darting at the anterior and posterior knee. By aligning the design lines with these dart termination points, I used dart manipulation to close up darts and transform flat panels into a pre-shaped, 3D volume. Further shaping was added to the upper thigh by curving specific seamlines to follow the natural profile of the leg.

This process allowed me to achieve a streamlined front leg construction and a fully contoured back panel. The result is a 360° shaping system that achieves a precise, anatomical fit while maintaining the collection’s signature aesthetic.

Hardware, COnstruction & SOFTWARE

Hardware: YKK #3.5 coil zipper tape, semi-lock reverse-bale sliders & rubber-covered metal pull tabs.

Waistband: Closure featuring pant hook and bar and Cobrax® snaps for a low-profile interface under gear.

Software: Optitex 2D, Browzwear Vstitcher

Documentation: Comprehensive Tech Pack developed in Excel.

Prototyping: self-constructed.

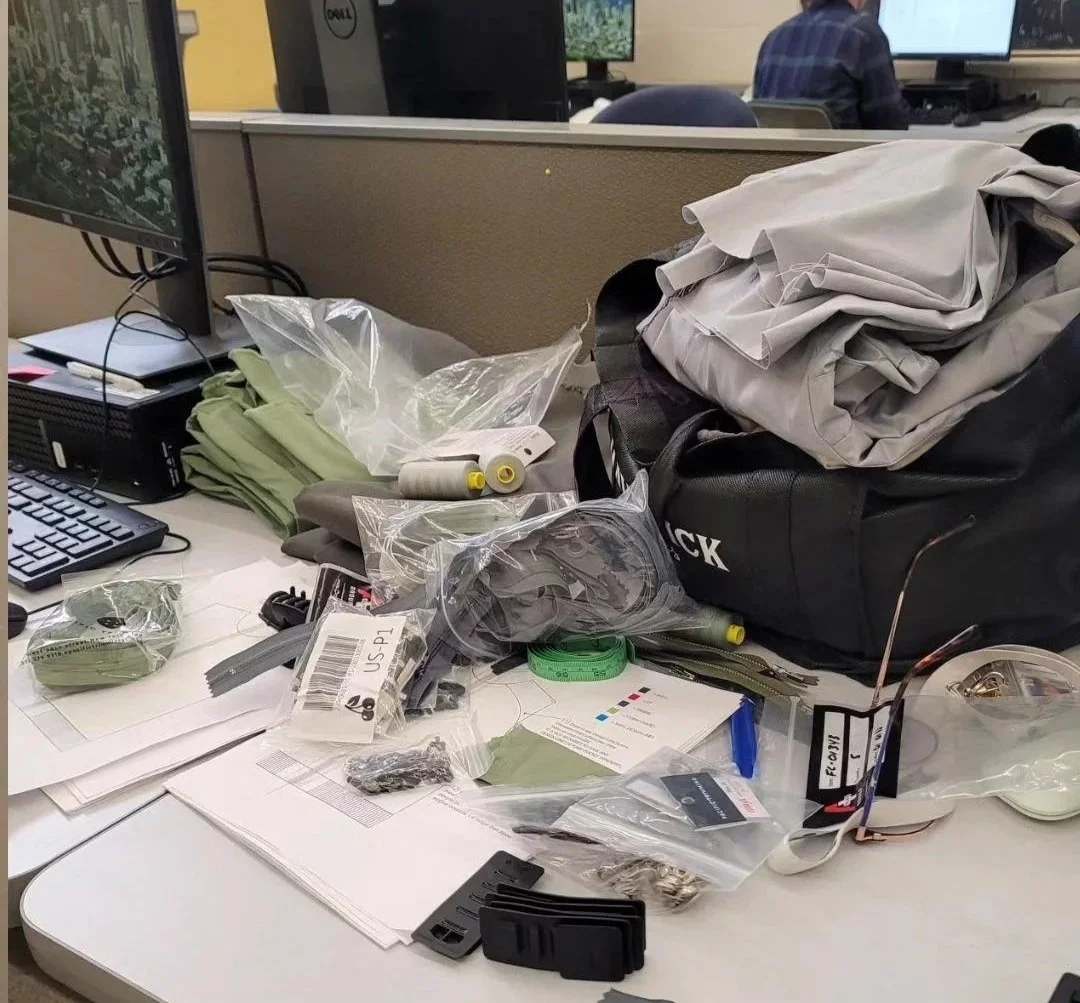

Tech Pack

Material Procurement: Assessing technical fabrics and a curated selection of premium hardware sourced nationwide for the final system.

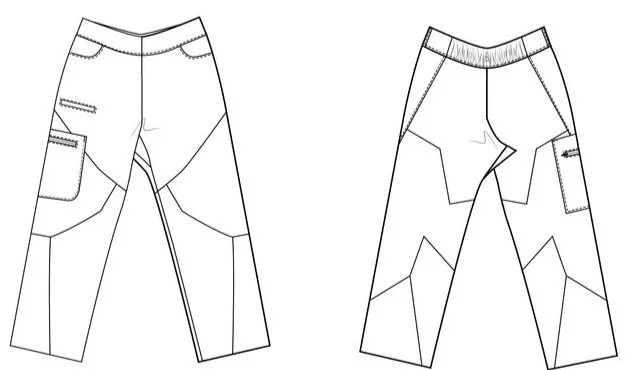

Title: 05. summit cargo pant

Category: Technical Shell | Fit: Relaxed / Articulated | Complexity: High

The Concept

The structural anchor for the lower body translating the "sharp vs. soft" aesthetic into a relaxed silhouette. The core technical challenge involved the acute mitered seams positioned across the back calf to maintain visual continuity with the mountain summit motifs of the upper layers.

Technical Specifications

Fabric: Lightweight Nylon Taslan | 105 gsm | 70D x 160D | Matte Cotton-Touch

Low-Profile Cargo: 4-panel minimalist gusseted zippered pocket designed to remain flush to the leg.

Hybrid Waistband: Half-elasticized construction for ease of entry and comfort while maintaining a clean, flat-front aesthetic.

Mobility & Airflow: Diamond-shaped crotch gusset lined with athletic micro-mesh and eyelet vents (embroidered) for thermoregulation.

Articulation: Ergonomic front and back knee paneling with a hidden double-knee layer.

Utility: Signature quick-access phone pocket, shock-cord hem casing.

Hardware: Low-profile YKK #3.5 coil zipper, semi-lock reverse-bale sliders with rubber-covered metal pull tabs.

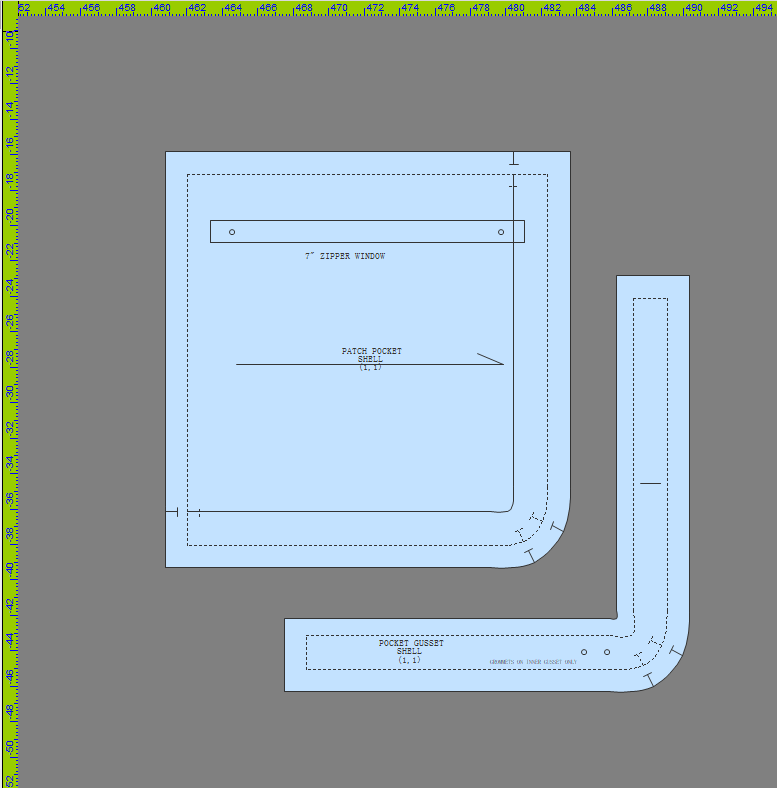

(up) 4-panel gusseted pocket pattern

Summit Cargo Pant- Final Sample - Front

Visualization of the "Mountain Peak" geometry across front and back leg panels, showing the alignment of mitered calf seams and the 3-panel articulated knee.

Summit Cargo Pant- Final Sample - Back

software & Execution

Patternmaking: Optitex.

Documentation: Comprehensive Tech Pack developed in Excel.

Prototyping: self-constructed.

Summit Cargo Pant Technical Sketches

Title: 06. kinetic utility short

Category: Technical Luxury Shell Short | Fit: Active / Tailored

The Concept

A personal exploration into Technical Luxury, serving as the system's most refined silhouette. Inspired by the architectural rigor of Veilance (Secant/Voronoi), this short utilizes a dual-tone "Warm/Cool" palette to maintain system coherency with the 04: Trek 360° Pant

The design is a study in "Invisible Complexity", balancing the sharp, angular geometry of the rear panels with softened curves on the front. By utilizing a waist facing instead of a traditional waistband, the garment achieves a continuous flow that emphasizes the premium drape of the Schoeller® textile.

Technical Specifications

Faced Waistline: A sophisticated internal facing removes all horizontal visual breaks. This particular finishing creates a seamless transition from body to garment.

Fabric: Schoeller® Doubleface Stretch Woven | 130 gsm (3.8 oz) | 4-Way Stretch | NanoSphere® DWR

Minimalist Pocketing: Front pockets feature a unique curved opening that terminates directly at the waist edge for a sleek, sophisticated entry. The back features a single-welt pocket on the right side for utility.

Stitching alternative: Both the hem and waist facing are seam-taped to the inner body. The minimal visible top-stitching creates a fluid, elevated aesthetic.

Software & Execution

Patternmaking: Optitex.

Documentation: Comprehensive Tech Pack developed in Excel.

Prototyping: self-constructed.

Kinetic Utility Short

Final Sample - Front and Back

Stage 1: THe BLueprint

Traditional block with identified waist dart andproposed geometric design lines.

stage 2: THE LOGIC

Dart manipulation: Transitioning 2D shaping into

functional panel seams.

Pattern Logic:

ACHIEVINg Intentional Simplicity

The technical short is often a "solved" silhouette, but I used this piece to focus on the details usually overlooked in mass production. My goal was an effortless aesthetic achieved through intentional decision-making rather than standard shortcuts.

Instead of relying on common waist darts or yokes that create visual noise, I used standard dart manipulation to integrate the shaping directly into the geometric seams. By fanning the design lines out to the outseam from the waist dart termination point, I eliminated the dart entirely. This resulted in a two-panel back construction with the 3D shaping built into the seam logic. It’s a simple technique used to ensure a sculptural fit while maintaining a completely clean exterior.

Stage 3: The ProDuct

Final technical pattern for the Kinetic Utility Short, color-coded for material allocation.

Photographer: Henry Jensen

Model: Tristan Sokol

Shoot assistant: Brady Larimer

Project Ownership & Credits

The design and development of CUAN:0 A/W 2023 Layering System, from research, concept, textile sourcing, and pattern making to final garment construction, was executed solely by this designer. This project represents a rigorous 12-week end-to-end technical exercise in self-construction.

I, Chi Vu Duong, would like to extend my sincere gratitude to the mentors and peers who contributed their time, technical insight, and support throughout the development of this collection. I never would have been able to make this happen without you.

Special thanks to: My Mother, Tristan Sokol, Eli Dechenne, Jasmine McKay, and Matthew David Paige, and